PEC Framing technology programm

Framing technology

PEC framing technology program

PEC Europe framing technology program comprises a wide range of PEC Framing channels in bright rolled and hot-dip galvanized material as well as the corrosion resistant variants in stainless steel. The product offering is complemented by the corresponding attachments, bolts and DIN elements

The advantages of the framing system find application in the areas:

- Steel construction

- Automotive Engineering

- Mechanical engineering

- Plant construction

The compatible system can also be used together with the PEC Cast-in channels.

PEC Framing Channels

PEC offers a comprehensive range of framing channels. In various designs and steel grades our hot-rolled and cold-rolled channel portfolio is flexible and versatile. They are suitable for use in a wide variety of applications such as:

- Fixing air ducts, pipes and electrical lines

- Anchoring of machines and racks

- Infrastructure projects (e.g. tunnels or bridges)

- Elevator construction

- Automotive

- Shipbuilding

PEC framing channels can be welded directly to the steel components. They are suitable for low, medium and high loads. Easy and quick installation on site with PEC screws greatly facilitate the work on construction site.

Product advantages

- Currently the only hot-rolled framing channel with ETA for 3D loading in combination

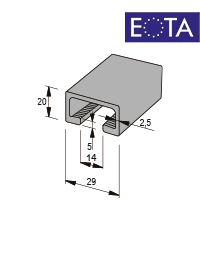

with toothed or serrated screws - New PEC-MZ-CE 29/20 is the first ETA-tested framing channel with teeth

- Optimized profile geometry for highest tension- or shear loads

- Flexible material selection depending on application: rollblank, hot-dip galvanized, stainless steel A4

- Corrosion protection with hot-dip galvanized or stainless steel A4 material possible

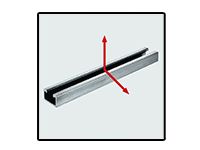

- Simplified installation due to the choice of 3 installation methods (welded, partially welded and subsequently doweled)

Product overview

| PEC Framing Channel, hot-rolled (ETA-certified) | |||

|---|---|---|---|

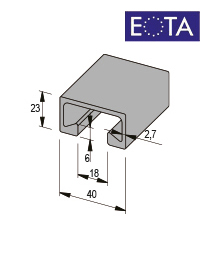

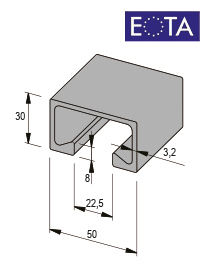

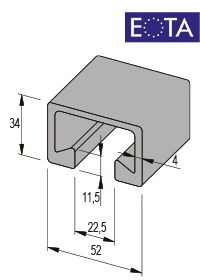

| PEC-MZ-CE 29/20 | PEC-M-CE 40/22 | PEC-M-CE 50/30 | PEC-M-CE 52/34 |

|

|

|

|

| WB, FV, A4 | WB, FV, A4 | WB, FV, A4 | WB, FV |

|

|

|

|

| HBC-T 29/30 | HBC-40/22 und HBC-40/22-N | HBC-50/30 und HBC-50/30-N | HBC-50/30 und HBC-50/30-N |

| Base material | Load conditions | ||

|---|---|---|---|

Steel |

Static/quasi-static |

Static 2D loading |

Static 3D loading |

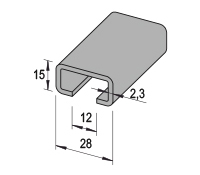

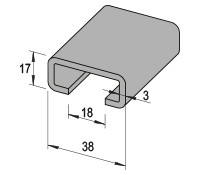

| Framing Channel, cold-formed (suitable for welding and screwing) | |||

|---|---|---|---|

| PEC-M-28/15 | PEC-L-28/15 (perforated) | PEC-M-38/17 | |

|

|

|

|

| WB, FV, A4 | FV | WB, FV, A4 | |

|

|

|

|

| HBC-28/15 | HBC-28/15 | HBC-38/17 | |

| Base material | Load conditions | ||

|---|---|---|---|

Steel |

Static/quasi-static |

Static 2D loading |

|

Material and surface finishes:

| WB | Steel S235 JR - 1.0038 (St 37-2), rollblank |

| FV | Steel S235 JR - 1.0038 (St 37-2), hot-dip galvanized |

| A4 | Stainless steel A4 1.4362 / 1.4401 / 1.4404 / 1.4571 |

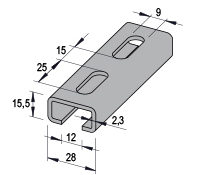

PEC Cantilevers, Bolts & Accessories

PEC Cantilever Brackets

PEC Cantilever Brackets can be used for fixing cable trays, pipes and other utilities. They are available for small, medium and high loads. Easy and quick on-site installation with the help of PEC Cast-in Channels and T-Bolts or with post-installed anchors.

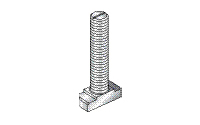

PEC Bolts & Accessories

The exceptional range of PEC Europe Framing-Channels is completed by various T-Bolts and DIN items. All are immediately available from stock.

Cable Holder System

PEC Cable Holder System

The safe load transfer of heavy wires and cables in tunnels, shafts and other utilities requires a stable fixture and appropriate support brackets. The PEC Cable Holder System consisting of cable holders and cable retainer Cast-in Channels ensures a proper storage system for cables and power lines within a short installation time and adjustment possibility.

The Cable holder channels are made of hot-dip galvanized steel and are available with back anchors for concreting or as plain channels for the subsequent fixing with dowels. The integrated rip line enables a quick, complete and clean removal of the filler. The slots themselves are additionally covered to achieve an optimal protection against the penetration of liquid concrete.

Due to a stamped slot with a distance dimension of 7,5 cm, the cable holders fixing is possible in any corresponding distances.

Advantages of PEC Cable Holder Channels

- Easy installation on existing formwork or existing walls

- Clean finish of concrete due to end caps

- The penetration of concrete into the interior of the channel is prevented by a plastic foam filler

- Easy removal of the filler by the integrated rip-liner

- High corrosion protection by galvanizing

- Can be cut on site arranging the anchors asymmetrically

- Available in different lengths