PEC Anchoring technology programm

Sandwich Panel Anchors

PEC Sandwich Panel Anchors (SPA)

New in our product range!

Sandwich panels are large multilayer, reinforced concrete façade elements. They consist of a facing layer, an insulation and a load-bearing layer. The main function of the PEC Sandwich Panel Anchor System is to connect the load-bearing and facing layers of sandwich panels and to transfer the forces acting on the facing layer to the load-bearing layer. In addition, restricting the expansion and contraction of the facing layer is avoided.

PEC-SPA Benefits

- Quick and easy installation of anchors and pins

- Reduction of mounting and planning effort

- Safety through building authority approvals

- EnEV-compatible with minimal thermal bridges through the fastening system

- Sustainability through stainless steel (materials A4 and D4 acc. to

- approval Z-21.8-2053, A2 on demand)

- Allows production of sandwich panels in positiv and negativ procedure

- Insulation layer thickness up to 400 mm possible

Download

PEC Anchoring Technology

PEC Cast-in Channels and T-Bolts

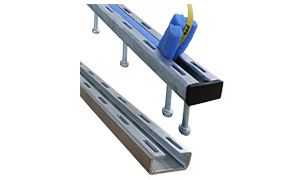

PEC Cast-in Channels in combination with appropriate T-Bolts are ideally suited for the quick, reliable and cost-efficient fixing of different construction elements.

PEC Cast-in Channels and T-Bolts are approved by the German Institute for Structural Engineering under the General Building Inspection approval. European Technical Approvals as well as National Technical Approvals are available.

Additionally customized solutions can be produced on request.

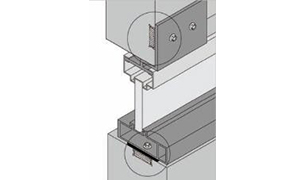

PEC Cast-in Channels type TU

PEC Cast-in Channels type TU are the best solution for safe, quick and cost effective fastening of trapezoidal steel sheets to reinforced concrete elements. The PEC Cast-in Channels type TU are officially approved by the German Institute for Structural Engineering.

PEC Brick Tie System

PEC Brick tie anchor systems ensure lasting and safe connections of masonry with concrete- or steel-constructions. The PEC Brick tie channels with rebending anchors will be cast-in the concrete construction.

PEC-TEC Brick Tie System

The PEC Brick tie anchor systems Type PEC-TEC are perfectly suited for the subsequent installation of walls. They guarantee a safe conjunction with the connecting wall.

Download

Cast-in Channels and T-Bolts

PEC Cast-in Channels and T-Bolts

PEC Cast-in Channels are ideally suited for the quick, reliable and cost-efficient fixing of different construction elements. The possibility to make simple and flexible adjustments saves time and money. PEC Cast-in Channels can be supplied in stainless steel or hot-dip galvanized.

Special designed PEC Cast-in Channels are also available on request.

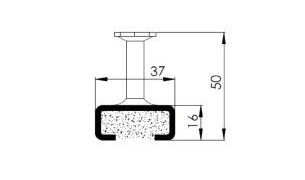

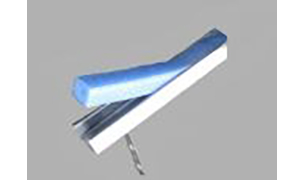

The special profiled foam filler protects the inside of the profile against concrete seeping into the profile. The PEC rip-line system allows the easy and complete removal of the filling from the profile. The clean removal of the filling prevents polystyrene residue at the construction site or at the precast plants.

An extensive accessory program provides ideal conditions for different application areas of the fixing and assembly technique.

We are one of the first manufacturers to develop our cold- and hot- rolled Cast-in Channel according to new approval ETA-16/0929 based on EOTA TR047. The new model has an international validity and customers benefit from reliable state-of-the-art testing and results, transparent assessment data and the application of EC-2 based design codes. In addition, the new provisions allow complex designs, considering variable design conditions.ineering under the General Building Inspection approval. European Technical Approvals, as well as National Technical Approvals, are available.

Advantages of PEC Cast-in Channels:

- European Technical Approval (ETA)

- Hot-rolled PEC Cast-in Channels are perfectly suitable for dynamic loads

- No damage to the load-bearing reinforcement

- Applicable in concrete pressure- and tensile-stress zones

- Corrosion resistant due to hot dipped galvanized or stainless steel

- Preliminary planning reduces construction time

- Time saving and avoiding fire hazard by using screwing instead of welding

- Readjustable at any time

- Easy assembly without complicate tools

- No drilling required, so no noise and no vibration

- Integrated PEC rip-line for clean removal of the filler

- Efficient fixing in rows

- Comprehensive product range

- Solid packaging as required on job sites, also suitable for resale

Download

PEC Customized Cast-in Channels

Our global engineering team is looking forward to assisting you in the development of unique product solutions. For any individual special

requests please contact our head office in Germany.

PEC Cast-in Channels type ES for pre-cast lintels

PEC Cast-in Channels type ES for pre-cast lintels are available for the profiles 28/15, 38/17 and 49/30. The profile and the bended bar are produced in stainless steel. A specially profiled foam filler protects the inside of the profile against concrete seeping into the profile. PEC Cast-in Channels type ES are offered in 150 mm.

PEC angles for pre-cast lintels are also part of our product range.

PEC Cast-in Channels with shorter anchors

PEC Cast-in Channels with shorter anchors for the special installation in thin concrete elements are available in 38/17.

Other profile dimensions are available on request.

PEC Cable Holder Channels

The Cable Holder Channels are made of hot-dip galvanized steel and are available with back anchors for concreting or as plain channels for the subsequent fixing with dowels. The integrated rip line enables quick, complete and clean removal of the filler. The slots themselves are additionally covered to achieve optimal protection against the penetration of liquid concrete.

Due to a stamped slot with a distance dimension of 7,5 cm, the cable holders fixing is possible in any corresponding distances.

Download

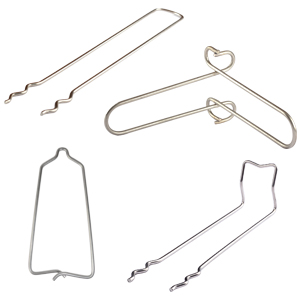

Brick Tie Anchor Systems

PEC-MS-D Brick Tie Anchor System

PEC-MS-D Brick Tie Anchor Systems ensure lasting and safe connections of masonry with concrete- or steel-constructions. After the Brick Tie Channel is cased in the concrete, the profiled plastic filling allows an easy and complete removal from the profile.

Thereafter the PEC-Brick Tie Anchors or the PEC Thin-Bed Mortar Anchors are inserted into the channels and pressed into the soft mortar joint. Due to the slipping ability of the anchors in the brick tie channel, the risk of masonry cracks is reduced considerably.

To make connections with steel constructions with welded channels, PEC Brick Tie Anchors are useable in commercially available profiles 28/15 and 38/17.

PEC-TEC Brick Tie Anchor System

The PEC-TEC Brick Tie Anchor System is an ideal solution to create connecting walls in a quick, reliable and safe way, without elaborate serrated brickwork joints. The system is very well suited to connect two brick walls or masonry walls with concrete walls.

To ensure a save connection of subsequently built-in masonry walls with existing walls, the PEC TEC Brick Tie Anchor System povides an optimal solution. The brick ties can be inserted into the brick tie channels, regardless of the brick dimensions.

The flexibility of the brick tie inside the channel maintains and reduces the risk of masonry cracking.

Download

Connecting Straps

PEC Connecting Straps

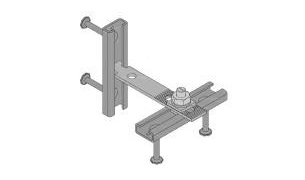

Two precast elements can safely be connected with already vertically and horizontally installed PEC Cast-in Channels with Toothed Straps which provide flexibility in all three directions.

The PEC Connecting Straps with serrations in the bracket and washer ensure a positive load transmission. The vertical and horizontal installation of the PEC Cast-in channels guarantees an exact and three-dimensional adjustment and fixing of the elements.

Download

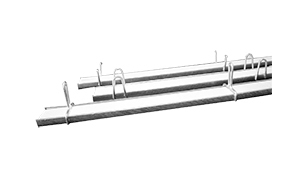

Cast-in Channels type TU for other applications

PEC-TU Self-anchoring Cast-in Channels

PEC-TU Self-anchoring Cast-in Channels in beams or columns are ideal for attaching trapezoidal steel sheet, windows and door frames as well as other construction elements. PEC-TU Self-anchoring Cast-in Channels make the work safe, fast and very cost effective. The Channels are available in three different dimensions with a standard length of 6.000 mm. They are galvanized and with a complete stuck filler to avoid that screws strike the concrete. Special lengths and material are available on demand.

The main advantage of Self-anchoring Cast-in Channels is that they work without anchors. The formed shape of the channel can provide sufficient anchoring into the concrete.

Download

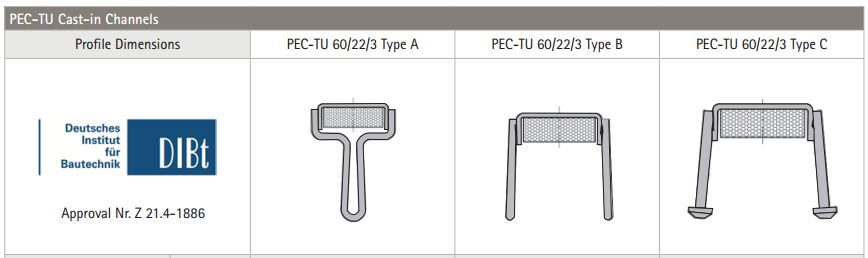

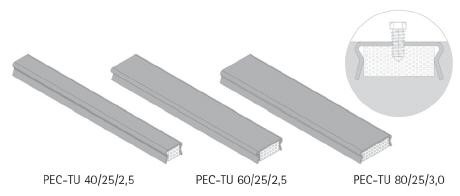

Cast-in Channels Type TU

PEC-TU Cast-in Channels

PEC-TU Cast-in Channels in concrete elements like columns or beams are an ideal way of fixing, trapezoidal steel sheets, windows and door frames as well as other construction elements with the help of self-taping screws. PEC-TU Cast-in Channels enable a safe, fast and very cost effective installation.

PEC-TU Cast-in Channels are available in three different channel types i.e. Type-A, Type-B and Type-C with a standard length of 3.000 mm. They are available in hot-dipped galvanized with zinc coating ≥ 50 μm according to approval Z-21.4-1886, stainless steel A4 and painted steel can be supplied on demand. PEC-TU Cast-in Channels are supplied with polystyrene filler to avoid that screws hit the concrete.

Types of PEC-TU Cast-in Channels

Advantages of PEC Cast-in Channels type TU:

- Approved by the German Institute for Structural Engineering

- Easy installation in the existing reinforcement due to different Anchor designs

- Load-bearing capacity in all three directions

- Technical sound, less slip connections

- Polysterene filler prevents the contact of the borers and screws with the concrete

- Rational steel sheet screwing

- Smoothly assembly without pre-drilling helps saving time

- Solid packaging as required on job sites

Download

PEC-TU Type A

PEC-TU Type B

PEC-TU Type C

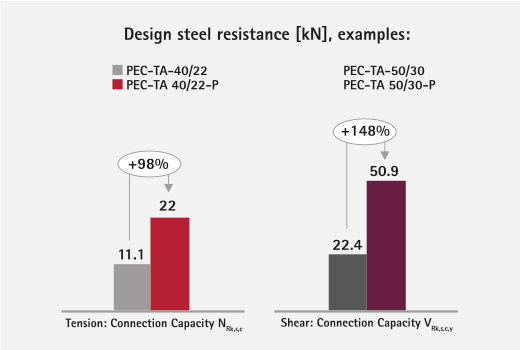

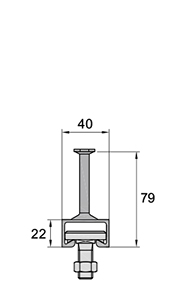

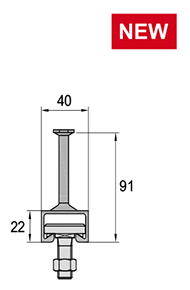

Ultimate performance: PEC-TA-P

PEC-TA-P premium anchor channel with optimized profile geometry redefines performance

Differences on a glance

- Up to 98% higher steel connection capacity under tension load

- Up to 148% higher steel connection capacity under shear load

- Comprehensive ETA assessment with data for 2D, 3D and fatigue resistance

- Higher concrete cone capacities by increased effective embedment depth hef

- Improved lip strength by optimized profile geometry

- Improved connection strength by defined and controlled socket forming

Save up to 40% of material costs!

Due to an improved anchor/channel connection and significantly higher steel resistance, in many applications bigger channels can be replaced by smaller stronger PEC-TA-P channels.

Download Information

| PEC-TA(-P) hot-rolled anchor channels | |||||

|---|---|---|---|---|---|

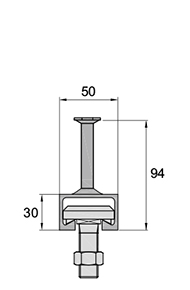

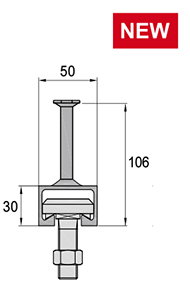

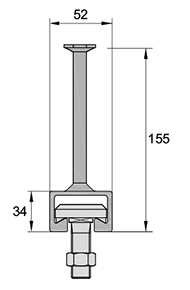

| Profiles | PEC-TA-CE-40/22 | PEC-TA-CE-40/22-P | PEC-TA-CE-50/30 | PEC-TA-CE-50/30-P | PEC-TA-CE-52/34 |

|

|

|

|

|

|

| T-Bolts | PEC-HBC-40/22 | PEC-HBC-40/22 | PEC-HBC-50/30 | PEC-HBC-50/30 | PEC-HBC-50/30 |

| Material | Carbon steel HDG ≥ 50 μm Stainless steel A4 |

Carbon steel HDG ≥ 50 μm Stainless steel A4 |

Carbon steel HDG ≥ 50 μm Stainless steel A4 |

Carbon steel HDG ≥ 50 μm Stainless steel A4 |

Carbon steel HDG ≥ 50 μm Stainless steel A4 |

Example: PEC-TA-CE-40/22-P anchor channel